Black Label Grading

Company-wide service digitisation

We took our client on a journey of digital transformation by optimising processes, modelling algorithms and improving workflow.

The challenge

BLG’s previous platform relied on paper order forms, creating friction for customers and making it difficult to track orders as they moved through the business. Customer communication was also slow and manual, adding further overhead.

Postage and third-party grading costs varied based on volume and handling, so we needed an efficient system that controlled costs while preventing orders from becoming mixed.

With grading often taking weeks, and sometimes longer during the pandemic, regular, automated customer updates were essential to maintain a positive experience.

OUR DELIVERABLES

A packing optimisation algorithm

We built a simulated annealing algorithm that tests 10,000 packing variations per run, using a ‘goodness score’ to find the most efficient bundles. Built in Excel with VBA, it’s easy to run, update and later integrate into the main platform.

Pokemon card indexing

With no existing card database, we built a tool to standardise identification and indexing. Creating it in Excel kept costs low and automated manual tasks such as third-party submission sheets, with data ready to migrate into the main platform.

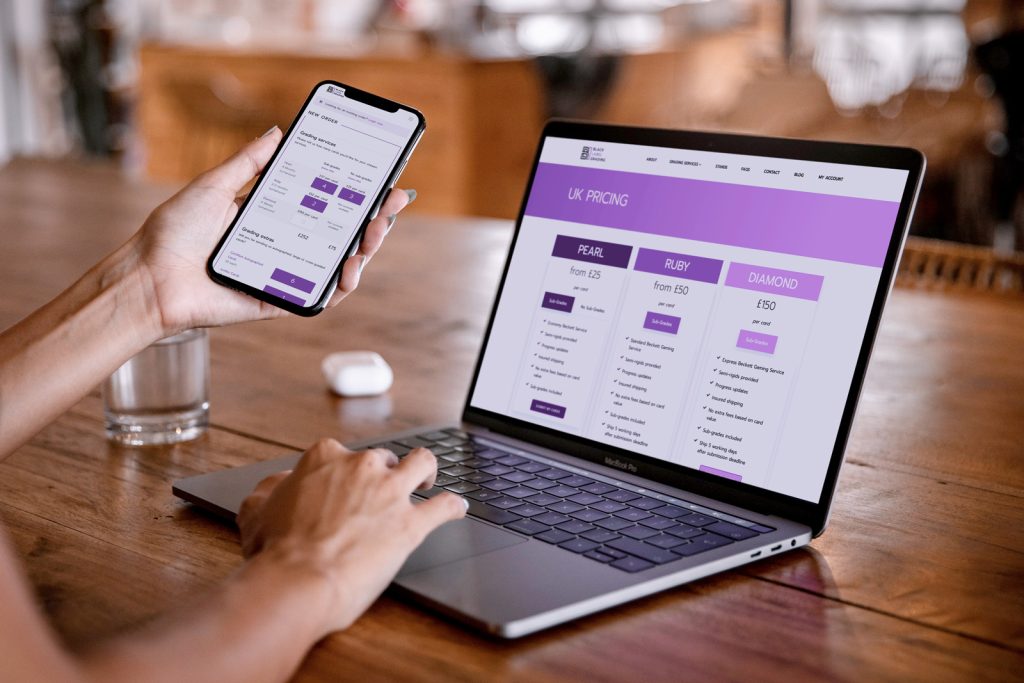

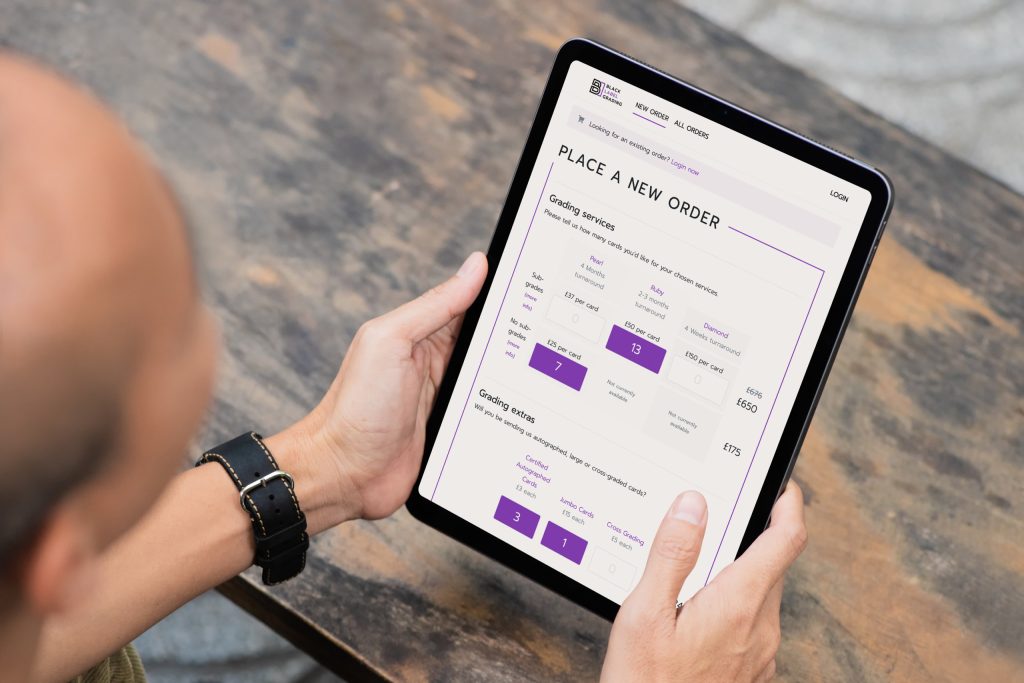

An ecommerce store

We replaced the WooCommerce store with a simple, accessible platform that removed manual ordering and enabled self-service. By integrating email, HubSpot and credit control, the site became a future-ready system that streamlined operations and upgraded the online presence.

Customer email updates

Digitising BLG’s workflow enabled milestone updates as orders move through each stage of the grading process. An API connection to HubSpot allows the website, database and CRM to share data, giving customers full visibility through automated updates.

International affiliate sales

We distilled the original system into a custom affiliate platform for European partners. Permissions limited data access, while bespoke calculations handled complex commission rules.

Continuous workflow management

To bring everything together, we applied service design to ensure each system worked seamlessly together. By balancing automation with human tasks, we reduced costs and replaced legacy processes with a more efficient operation.

Our approach

Our aim was to reduce operational pain quickly and cost-effectively. With a complex workflow to digitise, we used a phased, hybrid approach to deliver value fast.

Customer-facing and integrated processes were built into a cloud app. More complex offline workflows were developed in Excel VBA for faster, lower-cost iteration, with future migration in mind.

Variable postage and grading costs required a system that controlled spend while preventing customer submissions from becoming mixed.

With grading often taking weeks, and longer during the pandemic, clear, regular customer updates were essential.

“The team got to know us, our business and our ways of working. They listened, provided helpful input and automated many of our processes to get us ready for volume, and allow us to focus on growing the business. Whilst custom software is quite a technical undertaking, we felt well informed and in safe hands at each stage and are happy with the outcome of a brilliant series of projects.”

John Parker

Black Label Grading

Let's make something

Tell us how we can help you and your business improve processes and profitability.